CNC 4 & 5 Axis Milling and Turning Centers for all Your Precision Machining Needs

Facility List

Here at Kalman Manufacturing, we are constantly updating our facility to include the latest and greatest technology to help satisfy our clients. Realizing certain CNC machines are better for producing different parts and components, we do tremendous research before adding another CNC center to our floor. We do meticulous maintenance and cleaning of all our machines, keeping them in perfect condition to limit breakdowns and keep products being made and out the door. See below for a comprehensive list of all the CNC machines we have at our facility.

Our Machinery

Fastems – Grob 5-axis Horizontal FMS

(1) Fastems Flexible Manufacturing System for Lights Out Manufacturing

(2) Grob G350, Generation 2: 5-axis horizontal milling machining center. 24″ x 34″ x 30″ capacity, 117 tool HSK63 spindle with 16,000 RPM

(2) Grob G350, Generation 2: 5-axis horizontal milling machining center. 24″ x 34″ x 30″ capacity, 117 tool HSK63 spindle with 16,000 RPM

CNC 5-Axis 34 Pallet Automatic Workpiece Changer Mill Center

(1) DMG Mori NMV3000 DCG 34AWC 5-Axis Mill, Max Work Piece Ø13.7″ x 11.8″ High, 34 Pallet AWC, 300 Tool / 40 Taper / 12,000 RPM

CNC 5-Axis Mill-Turn Center NTX2000

(3) Mori-Seiki NTX2000 DCG 5-Axis Mill-Turn. Turn Ø 14.5″ – Bar feed Ø 2.5″ Turn Length 40″ Lower Spindle/Turret with single 5-axis Upper Head. 76 tool Capto C6 12, 000 RPM Spindle.

CNC 5-Axis Mill-Turn Center NT3150

(1) Mori-Seiki NT3150 DCG 5-Axis Mill-Turn, Turn Ø23.6″ – Bar Feed Ø2.0″ Turn Length 41.6″ Dual Lower Spindle / Turrets with Single Upper Spindle, 40 Tool / 40 Taper / 12,000 RPM

CNC Horizontal 6PP 6 Pallet System Machine Center

(2) Mori-Seiki NH5000 4-Axis Horizontal, Travel – 28″ x 28″ x 33″, 180 Tool / 40 Taper / 14,000 RPM

CNC Horizontal Machine Center

(4) Mori-Seiki NH5000 4-Axis Horizontal, Travel – 28″ x 28″ x 33″, 60 Tool / 40 Taper / 14,000 RPM

(1) Mori-Seiki NH4000 4-Axis Horizontal, Travel – 22″ x 22″ x 24″, 60 Tool / 40 Taper / 14,000 RPM

(1) Mori-Seiki NH4000 4-Axis Horizontal, Travel – 22″ x 22″ x 24″, 60 Tool / 40 Taper / 14,000 RPM

CNC Vertical Machine Center

(2) Mori Seiki SV-50 Pallet Vertical, Travel – 31″ x 20″ x 20 “, 40 Tool / 40 Taper / 10,000 RPM

(1) Hitachi Seiki VS-50 Pallet Vertical, Travel – 40″ x 20″ x 18″, 30 Tool / 40 Taper / 12,000 RPM

(3) Brother TC-32B QT Pallet Vertical, 4-Axis Trunion Vise Towers, Travel 21.7″ x 15.7″ 26 Tool / 30 Taper / 16,000 RPM

(1) Brother TC-31A Twin Pallet Vertical, Travel – 13.75″ x 9.8″ x 10″, 26 Tool / 30 Taper / 16,000 RPM

(1) Mori-Seiki DuraCenter5 Vertical, Travel – 31 ” x 20″ x 20″, 20 Tool / 40 Taper / 10,000 RPM

(1) Mori-Seiki DuraVert 5060 Vertical, Travel – 23″ x 20″ x 20″, 30 Tool / 40 Taper / 10,000 RPM

(3) Mori-Seiki DuraVert 5100 Vertical, Travel – 41″ x 20″ x 20″, 30 Tool / 40 Taper / 10,000 RPM

(1) Mori-Seiki FM-1 Vertical, Travel – 22″ x 16″, 20 Tool / 40 Taper / 8,000 RPM

(1) Hitachi Seiki VS-50 Pallet Vertical, Travel – 40″ x 20″ x 18″, 30 Tool / 40 Taper / 12,000 RPM

(3) Brother TC-32B QT Pallet Vertical, 4-Axis Trunion Vise Towers, Travel 21.7″ x 15.7″ 26 Tool / 30 Taper / 16,000 RPM

(1) Brother TC-31A Twin Pallet Vertical, Travel – 13.75″ x 9.8″ x 10″, 26 Tool / 30 Taper / 16,000 RPM

(1) Mori-Seiki DuraCenter5 Vertical, Travel – 31 ” x 20″ x 20″, 20 Tool / 40 Taper / 10,000 RPM

(1) Mori-Seiki DuraVert 5060 Vertical, Travel – 23″ x 20″ x 20″, 30 Tool / 40 Taper / 10,000 RPM

(3) Mori-Seiki DuraVert 5100 Vertical, Travel – 41″ x 20″ x 20″, 30 Tool / 40 Taper / 10,000 RPM

(1) Mori-Seiki FM-1 Vertical, Travel – 22″ x 16″, 20 Tool / 40 Taper / 8,000 RPM

CNC Turning Center

(1) Mori-Seiki SL-203 Lathe, Bar Feeder & Live Tooling, Turn Ø15″ – Bar Feed Ø2.5″

(1) Mori-Seiki SL-204 Lathe, Bar Feeder & Live Tooling, Turn Ø15″ – Bar Feed Ø2.5″

(1) Mori-Seiki DuraTurn 2050 Lathe, Bar Feeder, Turn Ø14.5″ – Bar Feed Ø2.625″

(1) Mori-Seiki Duraturn 2030, Bar Feeder, Turn Ø12.9″ – Bar Feed Ø1.75″

(1) Mori-Seiki DuraTurn 2050 Lathe, Turn Ø14.5″

(4) Mori-Seiki DuraTurn 2030 Lathe, Turn Ø12.9″

(1) Nakamura TMC-15 Lathe, Turn Ø12″

(1) Nakamura TMC-20 Lathe, Turn Ø14″

(1) Mori-Seiki SL-204 Lathe, Bar Feeder & Live Tooling, Turn Ø15″ – Bar Feed Ø2.5″

(1) Mori-Seiki DuraTurn 2050 Lathe, Bar Feeder, Turn Ø14.5″ – Bar Feed Ø2.625″

(1) Mori-Seiki Duraturn 2030, Bar Feeder, Turn Ø12.9″ – Bar Feed Ø1.75″

(1) Mori-Seiki DuraTurn 2050 Lathe, Turn Ø14.5″

(4) Mori-Seiki DuraTurn 2030 Lathe, Turn Ø12.9″

(1) Nakamura TMC-15 Lathe, Turn Ø12″

(1) Nakamura TMC-20 Lathe, Turn Ø14″

CNC Wire EDM Center

(1) Mitsubishi MV1200S 4-Axis Wire EDM, Travel – 15.7″ x 11.8″ x 8.5″ 15° Max Taper Cut / Min Wire Ø.004″

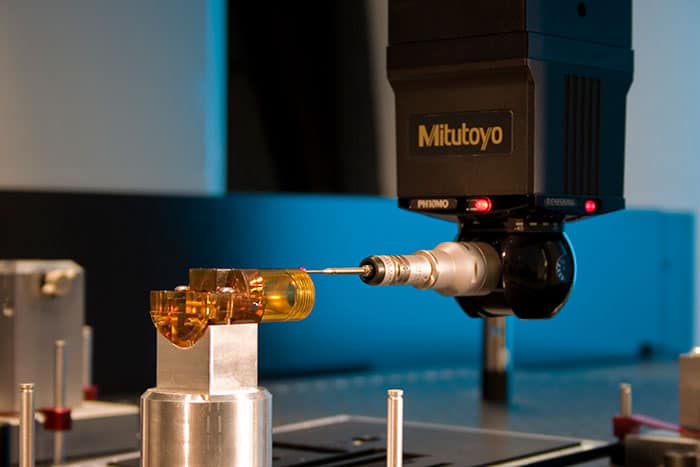

Inspection Equipment List

(3) Zeiss Contura G2 CNC CMM, Program Automated or Manual Inspections. Vast XT Gold Scanning probe head with multi-probe tool change stylus rack. Long run or repeat jobs using re-locating fixtures. Inspection Report Writing for First Article to Source Inspection Customer Reports.

Assorted Measuring Instruments

(1) Keyence IM 8030 Non-contact, high speed measuring. Capacity 300mm x 200mm x 75mm

(1) Keyence XM 5000 Handheld CMM. Capacity 2000mm x 1200mm x 1000mm

Optical Comparator, Surface Test and a selection of handheld measuring devices for all inspection criteria needs.

(1) Keyence XM 5000 Handheld CMM. Capacity 2000mm x 1200mm x 1000mm

Optical Comparator, Surface Test and a selection of handheld measuring devices for all inspection criteria needs.

Laser Engraver

(1) Keyence Laser Engraver, high speed serialization and graphics 300mm size capabilities.