WHY CHOOSE KALMAN MANUFACTURING?

About Our Company

Kalman Manufacturing of Morgan Hill, California is located in the heart of “Silicon Valley.” With over 38 years in business, we have developed into a state-of-the-art 42,000 square foot facility. With the practice of lean manufacturing and quality management, we can handle any project.

From a single part to a complex turnkey assembly, we ensure every part is made cost effectively and to the highest standards. Our world class customer service will give you confidence that we will work hard to fulfill your requirements. Our engineering and design group will work with your staff to help bring cost effective products to market in a timely manner, from development through production.

All of us at Kalman Manufacturing look forward to serving you and your company.

01 - Prototyping

PROTOTYPE MACHINING

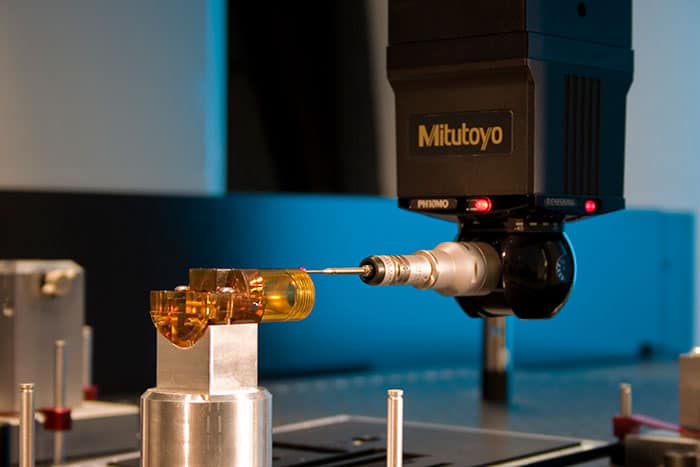

With our highly experienced and dedicated engineering staff, we have the capability to work with you in developing a new product or component. In the process of finding new and creative ways to streamline the manufacturing process of a current piece, our engineering team is willing and able to assist in iterating a new component design a superior product that is cost-effective and produced on time. Using state-of-the-art CNC machines and highly trained technicians, we take tremendous pride in our prototyping ability and unparalleled attention to detail. Our engineers will work with you every step of the way to bring up new ideas and to create a process that works best for the component. Here at Kalman Manufacturing, we are dedicated to helping our clients succeed.

02 - Production

PRODUCTION MACHINING

Here at Kalman Manufacturing, we produce a large amount of mechanical components and detailed sub-assemblies for a variety of industries, with a focus on the analytical instruments and medical device sectors. We continuously invest in the latest CNC and automation technologies to be Best in Class. From measuring devices, diagnostic equipment, to robotic surgery components; here at Kalman Manufacturing we assist in designing, developing, and delivering precise machined components that span many industries.

03 - DFM

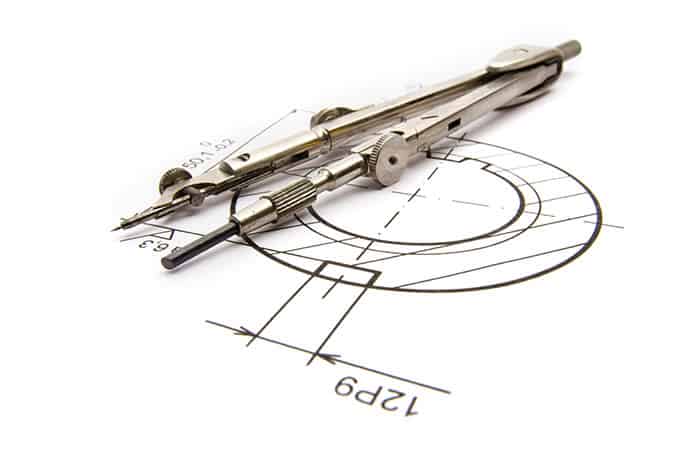

DESIGN FOR MANUFACTURABILITY (DFM)

Design for Manufacturing (DFM), the process of designing a part or component to be easily made in a repeatable fashion, is something we take extremely seriously here at Kalman Manufacturing. DMF is one Kalman Manufacturing’s key core competencies that has been developed over 38+ years of working closely with our clients. From working with your engineering team on part and process design early in the development lifecycle to finding ways to provide year-over-year cost reduction on long-standing production, our engineers are your dedicated staff to help ensure the part is being produced in the most efficient way. Furthermore, we will often provide design feedback where simple changes to the product will improve price, quality, or performance in the future.

04 - Mechanical Assembly

MECHANICAL ASSEMBLY

Here at Kalman Manufacturing, we take pride in being able to deliver final products exactly how they were designed. In order to do so, we've developed a mechanical assembly team to ensure that we aren't just producing individual components, but also assembling those components into their final configuration. In addition our processing engineering team has extensive technical experience from the aerospace, semiconductor, and automotive industries in developing assembly process instructions. This not only saves money and improves the overall quality of the assembly, but knowing how each sub-component is being used allows us to naturally engage in DFM work.

05 - Finishing

FINISHING

In order to be able to deliver parts on time and in their finished form, here at Kalman Manufacturing we have developed a supply chain of quality finishing houses to meet almost any customer surface preparation requirements, while maintaining the critical tolerances of the part. Our long-standing relationships with our finishing vendors allow us to work closely with them to establish best known methods and documented instructions for a particular finishing process and specific parts. While we support all standard machining finishing types, we have developed technical expertise in a few challenging ones, such as vapor polishing, which can be difficult to obtain consistent results from. Please contact us to discuss your finishing requirements.

01 - Prototyping

PROTOTYPE MACHINING

With our highly experienced and dedicated engineering staff, we have the capability to work with you in developing a new product or component. In the process of finding new and creative ways to streamline the manufacturing process of a current piece, our engineering team is willing and able to assist in iterating a new component design a superior product that is cost-effective and produced on time. Using state-of-the-art CNC machines and highly trained technicians, we take tremendous pride in our prototyping ability and unparalleled attention to detail. Our engineers will work with you every step of the way to bring up new ideas and to create a process that works best for the component. Here at Kalman Manufacturing, we are dedicated to helping our clients succeed.

03 - DFM

DESIGN FOR MANUFACTURABILITY (DFM)

Design for Manufacturing (DFM), the process of designing a part or component to be easily made in a repeatable fashion, is something we take extremely seriously here at Kalman Manufacturing. DMF is one Kalman Manufacturing’s key core competencies that has been developed over 38+ years of working closely with our clients. From working with your engineering team on part and process design early in the development lifecycle to finding ways to provide year-over-year cost reduction on long-standing production, our engineers are your dedicated staff to help ensure the part is being produced in the most efficient way. Furthermore, we will often provide design feedback where simple changes to the product will improve price, quality, or performance in the future.

05 - Finishing

FINISHING

In order to be able to deliver parts on time and in their finished form, here at Kalman Manufacturing we have developed a supply chain of quality finishing houses to meet almost any customer surface preparation requirements, while maintaining the critical tolerances of the part. Our long-standing relationships with our finishing vendors allow us to work closely with them to establish best known methods for a particular finishing process and specific parts. While we support all standard machining finishing types, we have developed technical expertise in a few challenging ones, such as vapor polishing, which can be difficult to obtain consistent results from. Please contact us to discuss your finishing requirements.

Kalman Manufacturing serves a number of industries.

From Medical Device and Healthcare to small satellites and electric vehicles

Kalman Manufacturing works to serve a wide variety of industries. The industries listed are just a portion that we have supported over the last 38 years and we are always looking for more. When it comes to manufacturing medical devices, we’ve become a leader in this area by accumulating a great deal of experience in working with the types of materials needed for the various applications component applications as well as assembling them according to tight specifications. These qualities and the discipline required to achieve them consistently have helped diversify our served markets.